Global supply chains are the lifeblood of today’s economy, interconnecting manufacturers, suppliers, logistics providers, and retailers across continents. In recent years, the drive to digitize these vast networks has gained momentum, driven by the need for greater efficiency, resilience, and transparency. However, despite the evident benefits, many organizations still face significant barriers to adopting new technologies in their supply chains. Overcoming these hurdles is essential for businesses looking to thrive in an increasingly complex and fast-paced global market.

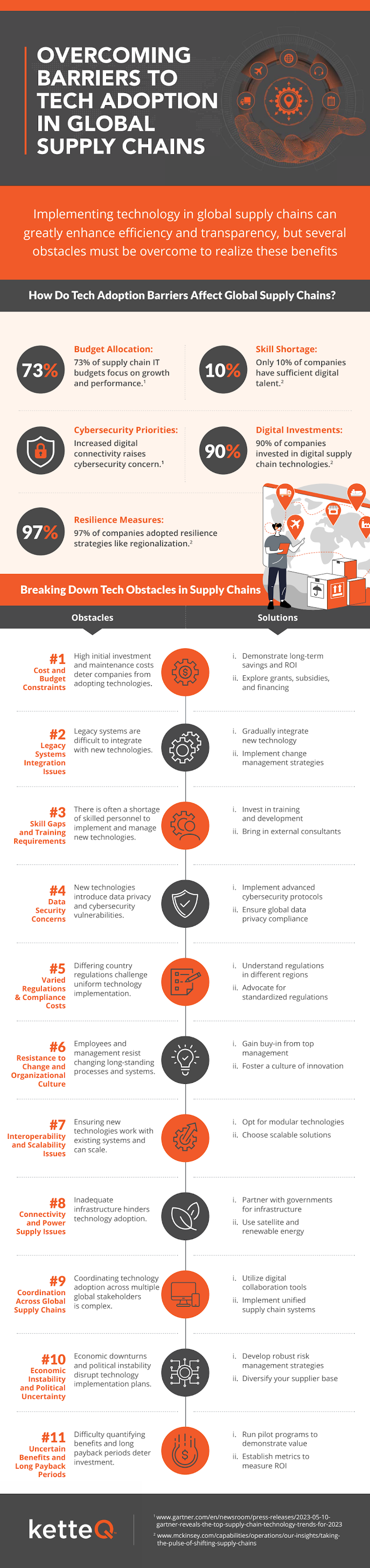

One of the most persistent challenges is the issue of legacy systems. Many companies, particularly large multinational corporations, operate with outdated ERP or inventory management systems that are difficult to integrate with newer technologies. These systems can limit visibility and flexibility, hindering the ability to respond quickly to market changes or disruptions. Replacing or upgrading such systems can be a costly and time-consuming process, often requiring a phased approach to minimize risk and disruption.

Another major barrier is the lack of internal expertise and digital culture. Implementing advanced technologies such as artificial intelligence, machine learning, and predictive analytics requires not only technical skills but also a cultural shift toward data-driven decision-making. Many supply chain professionals come from operational or logistics backgrounds and may lack the training or confidence to fully leverage these tools. Companies need to invest in upskilling their workforce and fostering a culture that embraces innovation and continuous improvement.

Data quality and interoperability are also key issues. For technology to deliver meaningful insights, data must be accurate, timely, and consistent across all nodes of the supply chain. However, data silos, inconsistent standards, and incompatible platforms often obstruct seamless data flow. Collaborative platforms and APIs that facilitate communication between disparate systems are crucial to overcoming these obstacles.

In addition, many organizations struggle with aligning tech adoption with clear business goals. Without a strategic vision, technology investments can lead to disjointed solutions that fail to deliver real value. This is where specialized partners can play a critical role. For example, ketteQ, a supply chain planning company, offers integrated planning solutions that bridge operational gaps, enhance demand forecasting, and support better decision-making across the supply chain.

Finally, there is often resistance to change, especially among stakeholders who fear disruption or job displacement. Transparent communication, involving teams early in the adoption process, and demonstrating quick wins can help build trust and reduce friction.

In conclusion, while the path to technology adoption in global supply chains is fraught with challenges, these barriers are not insurmountable. With a combination of strategic planning, investment in talent and tools, and strong leadership, companies can unlock the transformative potential of digital supply chains and position themselves for long-term success.